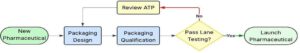

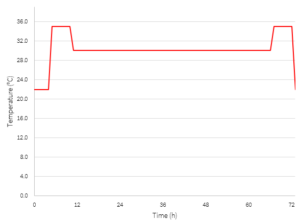

Ambient Temperature Profiles (ATPs) are a set of temperatures programmed into a thermal testing chamber or simulation software that are meant to mimic the common temperatures that a cold chain package will experience on its way to the end-user. The profile is needed for the Design Qualification (DQ) and Operational Qualification (OQ) process of validating cold chain packaging.

Choosing the correct profile to validate cold chain packaging is a crucial step in ensuring that any Performance Qualification (PQ) and lane testing are executed smoothly, minimizing delays in a product’s launch. Designing with the incorrect profile is one of the leading factors for temperature excursions in cold chain shipments due to unexpected hot or cold excursions.

The process of choosing the correct Ambient Temperature Profile can be a tough decision. Lane data is often not available when launching a new pharmaceutical or using a new 3PL distributor. To overcome this obstacle, many industry-standard profiles have been developed to facilitate an initial qualification of cold chain packaging. These profiles are often developed using different methods, including analyzing seasonal weather data, reviewing typical shipment method routes and their respective temperatures, and averaging the temperatures recorded from real-world shipments.

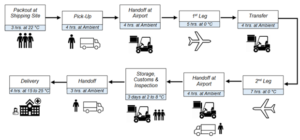

Industry groups like ISTA, packaging manufacturers such as Sonoco Thermosafe and TOPA Thermal Packaging, and governing bodies including the World Health Organization, the Department of Defense, and the German Institute of Standards have developed ATPs that integrate seamlessly across various shipping modes. An evaluation or mapping of the shipping lane helps you to best fit an industry standard profile that most closely matches what the packaging will experience in the real world. Below are considerations for each shipping method when choosing an ATP for your DQ and OQ qualifications.

Ground Shipments

While it’s the most cost-effective form of shipping, ground shipments typically have the highest amount of temperature excursion risks. The ambient temperature follows the weather data of the package’s current location requiring the package to be robust enough to endure the high heats of Summer as well as the chilly cold of a Polar Vortex in the Winter.

Next Day Air

More expensive service options such as Next Day Guaranteed or 2-Day Guaranteed Delivery will be a more expensive up-front cost but can greatly reduce the need for robust packaging and minimize temperature excursion risk. Due to the expedited nature of the shipment, the package spends minimal time in one place and is not typically affected by the weather. Though the high-altitude environment of an airplane can create unique cold excursions with temperatures in the luggage department at 5°C to 15°C even when weather temperatures are 35°C in the same area.

International

The conditions for international shipping can vary widely from continent to continent creating a high-risk shipping environment. Delays are common with Customs or security checks which can lead to a package being exposed to the outside weather for long durations. Typically, a worst-case scenario profile is recommended to ensure these high-cost shipments do not have to be repeated.

Contact Us

If you need assistance with selecting an ambient temperature profile for your packaging qualification or want to review if the ATP you utilize today is the best fit for your shipping method, please reach out to EFP and we would be happy to set up a consultation.

Written by Andrew Klasek, Product Engineering Manager.

Andrew began his career in the Environmental Chemistry field before coming to the packaging world where he currently runs the EFP Cold Chain Laboratory which develops shipping solutions for pharmaceutical and food shipments. Andrew also participates in the creation of whitepapers and industry guidance documents with the ISTA Pharma Committee covering topics such as developing temperature profiles for testing, lane testing, and simulation software.

Keep up with all the latest EFP News!