A risk assessment has become common practice for both product development and pharmaceutical shipping. These two fields intersect when shipping cold chain products, which require specialized, highly engineered packaging to ensure the stability of a temperature-sensitive product during its delivery to the end user.

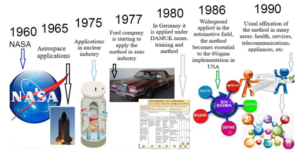

A common risk assessment tool developed by the United States Army and perfected by NASA, known as the Failure Mode and Effects Analysis (FMEA), can be utilized to identify possible failure points in a design or process. This assessment tool assigns the potential failure point a risk rating. The rating signifies when steps in a process or features in a design have high risk of failure modes, such as temperature excursions or physical damage.

To initiate an FMEA for a cold chain product, the analyst must outline the steps for utilizing the cold chain packaging at their facility and shipment expectations to the end user. Common process steps may include:

Each step can then be assessed a potential failure mode which is evaluated for its severity of impact, the likelihood it would occur, and what controls are currently in place. These three factors will determine if the risk is under adequate control or if corrective actions should be taken.

An example of a potential failure mode during the shipment of a cold chain pharmaceutical is an adverse weather event such as a blizzard. The severity of impact is high since sub-freezing temperatures can lead to the pharmaceuticals freezing. The likelihood of occurrence in this situation is medium depending on the shipping lane, and controls may already be in place such as sub-freezing temperatures tested during the packaging’s Operational Qualification. For this case, the failure mode should be under control and have a low risk of occurrence, but if controls were not in place or occurrences are found to be high over time, further corrective actions would be needed.

A risk assessment of the cold chain packaging can add an extra layer of protection to your shipping operations:

For more information on controlling the risks in your cold chain distribution, reach out to the experts at EFP who can consult you through your own FMEA.

*The ISTA Pharma Committee has also released a Whitepaper to familiarize the industry with risk assessment in the “Shipping and Distribution Risk Assessment” ISTA PCW-02 document released in January 2024 that can be downloaded at this link free of charge.

Written by Andrew Klasek, Product Engineering Manager.

Andrew began his career in the Environmental Chemistry field before coming to the packaging world where he currently runs the EFP Cold Chain Laboratory which develops shipping solutions for pharmaceutical and food shipments. Andrew also participates in the creation of whitepapers and industry guidance documents with the ISTA Pharma Committee covering topics such as developing temperature profiles for testing, lane testing, and simulation software.

Keep up with all the latest EFP News!