Cold chain packaging follows a fairly standard protocol: design a solution to ship in the warm months of the year and design another solution to ship in the cold months of the year or spend a lot more money to ship the same solution year round. The design gets qualified against a Summer profile and a Winter profile (typically the ISTA 7E Summer/Winter profiles) and the packaging is considered operationally qualified. Once the distribution facilities begin shipping the products in the cold chain packaging, this question will usually arise from the operations management in the spring or fall: “When do we switch the pack out from Summer to Winter?” This question is typically addressed by the Quality Assurance or Risk Manager of the distribution facility, but the COE Laboratory also provides guidance and tools on when to make this switch.

Lane data for your shipping lanes is going to be the most accurate indicator for when to use Summer packaging or when to use Winter packaging. By shipping your product with a Data Logging Device on the outside of the packaging, the ambient temperatures experienced by your package can be recorded. Performing this lane data procedure once or twice a month can produce a log of the ambient temperatures experienced by the packaging throughout the year. This logged data can then be compared to the testing profiles that the packaging was qualified with to determine the best time to make the switch from a Summer pack to a Winter pack or vice versa. While using the lane data as a determination is the most effective way for determining when to switch, the process can become cumbersome when multiple packaging systems are being shipped to different parts of the country which would each need their own sets of lane data.

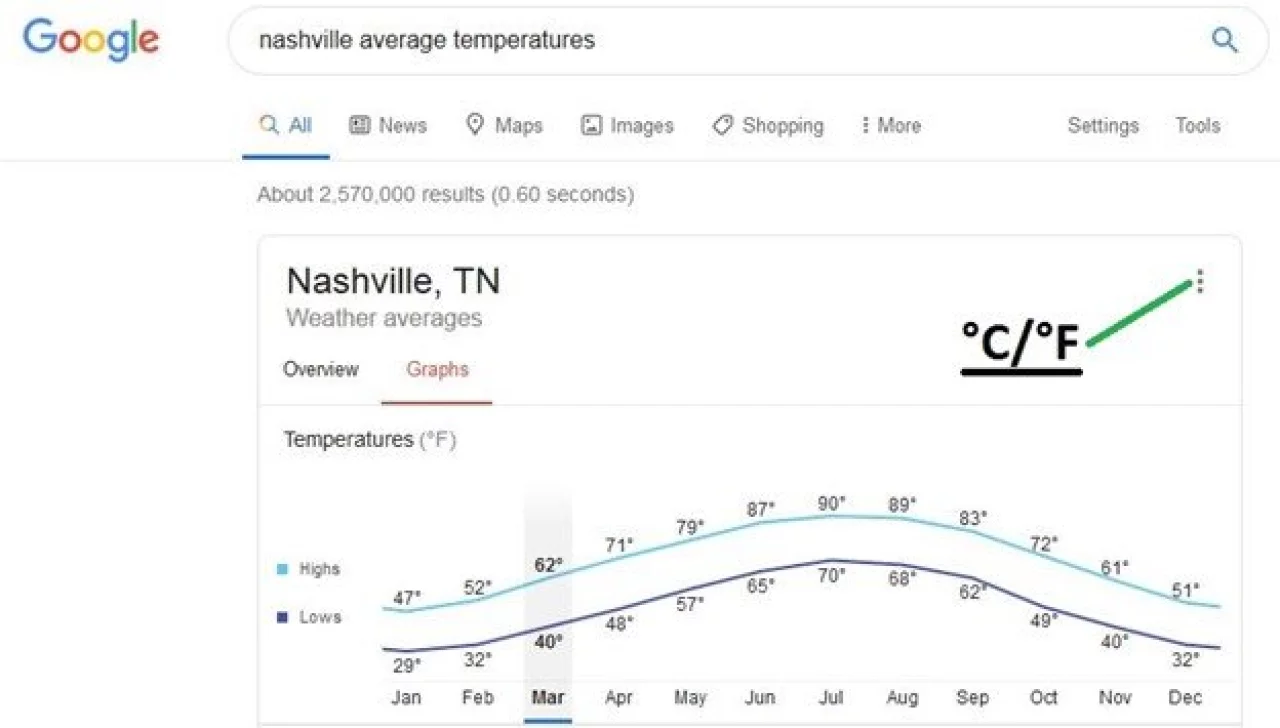

When lane data is not available or is too difficult to accumulate, there are other tools that can be used to determine when to make a seasonal packaging switch. The Google Search Engine offers a very handy Almanac Tool for viewing the average high and low temperatures for a city that can be compared month by month to your packaging’s qualification report to determine when the switches should be made in seasonal packaging. Simple go to Google’s main page, search for “[City Name] average temperatures” and click the search button. A list will appear showing the weather data for a few months, simply click the “Graphs” view to see the average high and low temperatures for each month throughout the year. This method works most efficiently when shipping to different parts of the country; Miami shipments might need the seasonal change to occur in November whereas your shipments going to Denver might need to switch in August.

Other solutions are available to help with the seasonal switch problem as well. Simulation software can be used to put your currently qualified shipping solution through more vigorous testing such as running the summer pack out configuration with a mild winter profile to see what thermal changes are experienced by the payload. By running the pack out against milder and more extreme Summer and Winter profiles, a min and max temperature range can be determined to help with the seasonal switch decision. Some organizations will also try to alleviate as much risk as possible by either designing a spring and fall solution to go along with the summer and winter solutions or by designing a single universal solution that works every month of the year. These two methods are great solutions for minimizing the risk associated with switching seasonal packaging but are usually avoided due to the extremely high cost of a universal packout (usually 10-30 times the cost of single season packaging) and having a packout for each season means four pack out configurations to use and store for each size of shipment which can be a nightmare for operations. The International Safe Transit Organization has also released best practice guidance documents that include analysis tools for comparing your lane data with both weather data and chamber testing profiles.

If you need consulting on when to switch your packaging from a summer pack out configuration to a winter or vice versa, or would like to have your current packaging tested at with a different thermal profile to see how it performs in the spring/fall months using a thermal chamber or simulation software, contact us today and we will help to decrease the risk associated with this changeover.

Whether you'd like to get to know more about EFP, learn more about our career opportunities or if you'd like to potentially do business, we'd love to talk with you.